-

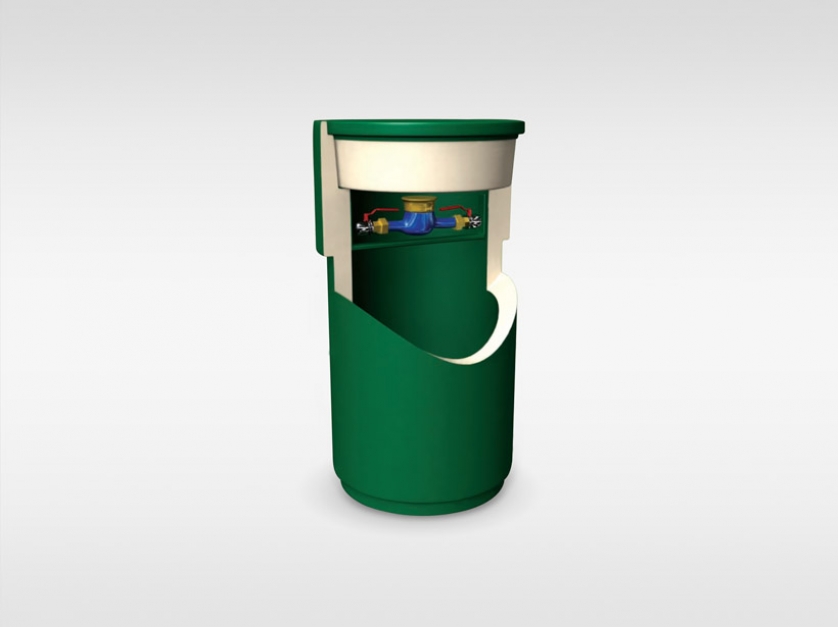

ISOLATED WATER MEASURING WELLS PM400 AND PM500

Water measurement wells PM400 and PM500 are meant for connecting individual consumers to the municipal water main. The wells are designed and constructed according to the climatic conditions of the Baltics and Nordics. ROTONS’s Ltd. PM500 isothermal wells received 3rd place in the Import Substitute Category of the Export and Innovation Award organized by the Latvian Investment and Development Agency of Latvia (LIAA) in 2011.

WORKING PRINCIPLE

The meter is set at a depth of 30-40 cm, so it is easy to control and use. The geothermal heat output of the Earth and ground waters at sufficient insulation of wall wells and surface during the winter provide a positive temperature inside the wells, even at the lowest outdoor air temperatures. So the meter, which is placed near the surface, does not freeze and continues normal operation. PM500 wells are suitable for installation in areas where the outside air temperature can reach -30C and the frost zone can be down to 1.5 m, as well as for the construction of water supply in areas with high groundwater levels.

CONSTRUCTION

The double frame of the PM500 well is made of high density polyethylene (HDPE). Internal diameter of the well’s frame in water meter installation area: 500 mm. Well’s height: 1200 mm. Partition space filled with polyurethane foam, which provides an effective thermal insulation. Polyethylene frame is hermetically sealed, so the insulation layer does not affect the existing ground water and humidity.

The thickness of polyurethane insulation is from 60 mm at the top to 35 mm at the bottom of the well. Thermal conductivity coefficient of polyurethane λ≈0.27 W/mK – the lowest compared to other insulation materials (e.g. polystyrene λ≈0.35 W / mK λ≈0.35 W/mK).

The well is equipped with a thermal insulation cover made of polyethylene with a 140 mm thick layer of polyurethane. This material combination also provides additional mechanical rigidity. The PM500 well can be completed with connecting pipes, water meter nodes and telemetry system. Depending on the installation site, a light polyethylene cover or any cover appropriate for EN124 load can be chosen:

• in a driving zone well is set with D400 load cover;

• in pedestrian zone well is set with C250 load cover;

• in green zone well is set with B125 load cover.

ADVANTAGES OF PM400 AND PM500 WELLS

• compact and easily transformable structure;

• low construction costs;

• simple service of counter;

• rigid double-wall construction;

• encapsulated insulation material;

• long-lasting lifetime.

TECHNICAL SPECIFICATIONS

• body: high density polyethylene HDPE;

• insulation: polyurethane foam; density of 35–40 kg/m3; λ≈0,27;

• connecting pipes: polyethylene from DN20 to DN32 (PM400) or from DN20 to DN40 (PM500) in accordance with LBN 222-15;

• cover: high density polyethylene HDPE; on driveways or pavements wells can be installed with floating class C250 or D400 cast iron covers;

• fittings: valves, couplings, fittings made of brass for use in drinking water systems;

• weight (without covers): 26 kg.

Any manufacturer’s system DN15, DN20 and DN25 water counters can be installed in wells. The customer determines meter manufacturer, accuracy class and data reading method. Before installing wells, binding legal regulations, such as LBN 222-15 Water supply external networks and structures, should be taken account of.

-